What is the difference between PET Silver label and PET paper

The difference between PET Silver label and PET paper can be summarized in the following aspects:

Appearance and color:

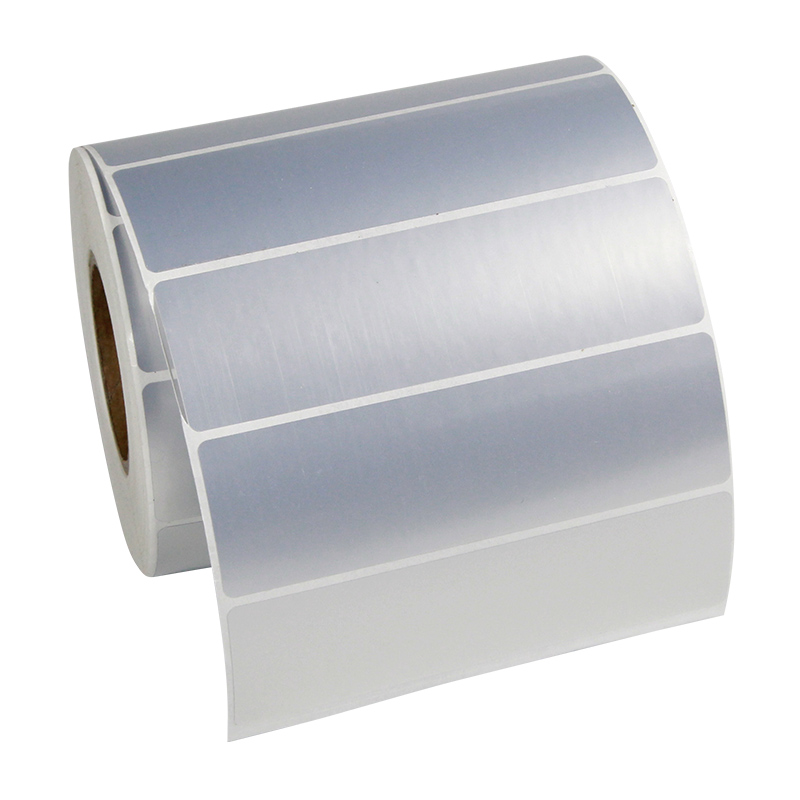

PET Silver label: The surface is silvery white, usually with matte and bright silver distinctions, giving a metallic appearance.

PET paper: A variety of colors, not only silver, but also including matte white, bright white, transparent and other colors.

Surface treatment:

PET Silver label: The surface may be specially treated, such as matte finish, plain light, bright light, etc., to meet the visual needs of different labels.

PET paper: The surface treatment may be more diverse, depending on the specific use of different treatment options.

Application scenario:

PET Silver label: Due to its metallic appearance and excellent durability, it is often used to enhance the product image or attract attention, such as high-end commodity labels, equipment nameplates, etc.

PET paper: Because of its diverse colors and good durability, it is widely used in the identification, packaging and information recording of various products.

Physical characteristics:

Both have the basic characteristics of PET materials, such as water resistance, oil resistance, tear resistance, and high temperature resistance. However, PET Silver labels may have additional stain and corrosion resistance due to surface treatment.

Cost:

PET Silver label: Due to the special finish and metallic appearance, its production costs can be relatively high.

PET paper: Costs can vary depending on color and complexity of handling, but will generally be more economical than PET Silver label.

In summary, there are significant differences between PET Silver label and PET paper in terms of appearance, color, surface treatment, application scenarios, and cost. These differences allow both to play an important role in their respective areas of expertise.