Specification description of wax based carbon strip

Specification description of wax based carbon strip

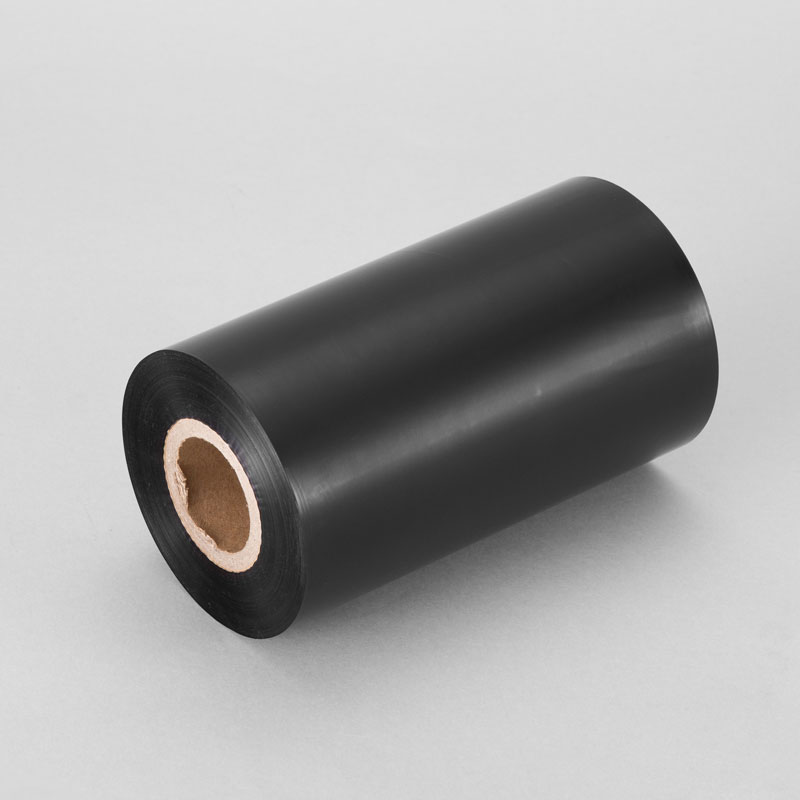

Wax-based carbon strips, as an efficient and economical printing solution, are available in a variety of specifications and models to meet the needs of different industries and applications. Here are some common specifications for wax-based carbon strips:

Width: wax-based carbon strip width range is wide, common 30mm, 40mm, 50mm, 60mm, 70mm, 80mm, 90mm, 110mm and other sizes. These different widths of carbon tape can be adapted to different sizes and shapes of printing needs.

Length: The length of the carbon belt is also an important factor affecting its use effect and cost. Common wax-based carbon strip length is 100m, 300m, etc. Users can choose the appropriate length according to the actual printing needs.

Material and coating: wax-based carbon strip is mainly coated with wax and carbon black, which determines the melting point of the carbon strip. Because the melting point of wax is much lower than that of resin, the printing temperature required when printing with wax-based carbon strips is relatively low.

Color: Wax-based carbon strips are usually offered in black as the standard color, which is designed to meet most printing needs. However, customers with special needs can also customize other colors of carbon strips.

Coil and axis: The coil of carbon tape is divided into outer carbon and inner carbon, depending on how the carbon tape is wound. At the same time, the carbon belt axis is also available in different sizes such as 1 inch and 1/2 inch to meet the needs of different printers.

Applicable media: Wax-based carbon tape is suitable for a variety of printing media, including ordinary paper, coated paper, tag, glazed paper, smooth paper and synthetic paper. It is especially suitable for materials with slightly convex surfaces, which can provide good printing results.

In addition, in order to ensure the best performance and service life of the carbon belt, the storage and use environment is also a factor that needs to be considered. In general, wax-based carbon strips should be stored in a dry, cool environment, away from direct sunlight and humidity. At the same time, care should also be taken to avoid excessive extrusion and damage during transportation and storage.